Services

Our production processes

As a company providing assembly of electronic circuits for final users, we have been co-operating with international development institutions and universities. In this way, our buyers can be relieved of the “burden” of their own production of electronic circuits and can focus on other phases of production. In our response to different project challenges, we use our long experience, reliability, stability and professionalism proven by our regular and new customers.

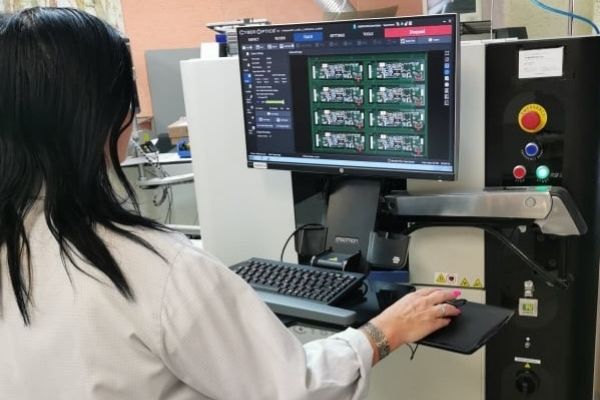

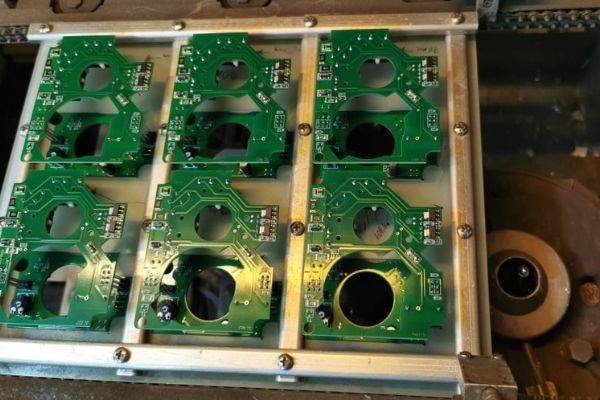

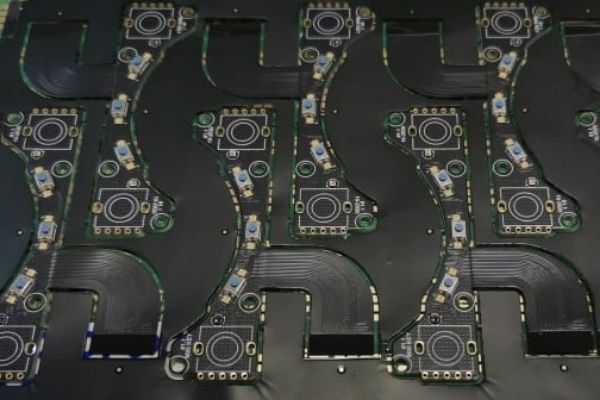

SMT-technology

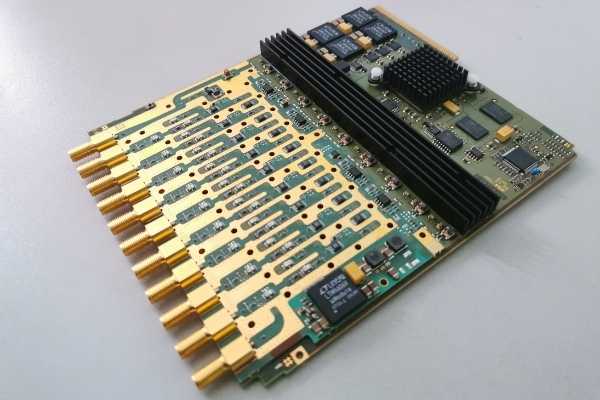

Our line for assembly of one or multi-sided PCB boards with SMD-components enables the assembling of components from the size of 01005 to large demanding BGAs. We provide the composition from one to a several thousand pieces. In the SMT technological process, the device 3D AOI is used to control the application of soldering paste on PCB as well as the soldered component after it arrives from the reflow soldering. This technological process and our experience ensure the quality of assembled boards.

THT-technology

Just like with SMT, we can use the THT technology to assemble one to a thousand pieces. A selective soldering of THT components on an automatic line machine Ecoselect 2 enables the repeatability of the soldered joints in nitrogen atmosphere under the same conditions. Using our 10-year experience with selective soldering, we strive to create perfect joints.

Manual soldering

Experienced colleagues use manual soldering in completion of the joints, repairing the circuits following the demands of the clients and whenever there is no possibility for automatic machine soldering. Permanent training and high-tech soldering equipment, provide us with high-quality manually soldered joints.

Research and development

With our experience and expertise, we provide counselling on how to ensure optimization of the product development phase. In case basic components for a requested project cannot be supplied, we enable the search for the alternative ones.

In co-operation with external experts, we develop and produce testing equipment following the demands of the clients, such as a device for cable set testing during assembly which controls the correctness of the assembled cable set.

Our technology

High level of our technological development is reflected also by our high-tech equipment:

- line for SMD assembling up to 35,000 components/h

- line for automatic selective soldering

- automatic optical inspection - 3D AOI

- desk station “Vision Z” for a manual visual inspection of soldered components

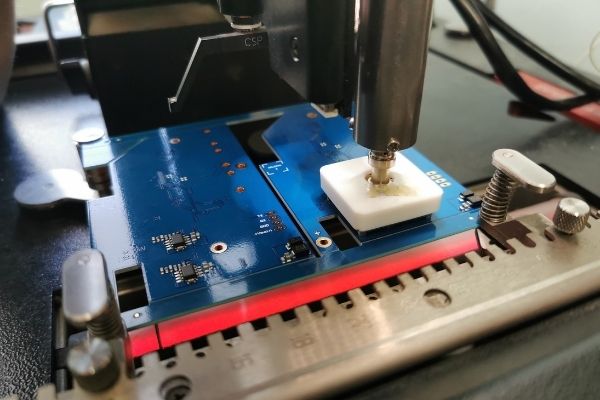

- rework station Martin Expert 10.6 HV

- manual solder paste printer

- manual pick and place machine